The Missing Link: How Net-Zero Supply Chains are Mitigating Climate Change

Supply chains generate around 60% of all global carbon emissions, making them a critical target in the fight against climate change. In a 2022 UNGC Accenture CEO study, researchers found that 49% of CEOs stated they were grappling with supply chain interruptions due to extreme climate events. Further, 50% of CEOs in the food and beverage industries are concerned about accessing natural resources due to extreme weather, and a striking 72%, of CEOs surveyed, stated that sustainability is a priority as they handle the fallout from the pandemic.

CEOs are not the only ones taking note of these phenomena, as they have increasingly hit the headlines in recent years. For example, the “freak” freeze in Texas between February 10th and 27th of 2021 caused the worst involuntary energy blackout in US history. Three major semiconductor plants closed, which worsened both the global semiconductor shortage as well as slowing microchips for vehicles – a shortage which we are still experiencing to this day.

Across the Atlantic, Europe has experienced increasingly severe flooding of the Rhine river upon which several energy production plants and other industries rely, as well as causing fatalities and home destruction. For scale, portions of the Palatinate and North-Westphalia regions of the river which typically experienced around 80 liters of rain per square meter through the month of July were hit with 148 liters of rain within 48 hours. Many of the communities closely tied to the river both personally and economically do not have the infrastructure in place to withstand these effects, and would feel loss over the course of years or even decades should another “freak” weather event occur.

What Are Net-Zero Supply Chains and How They Work

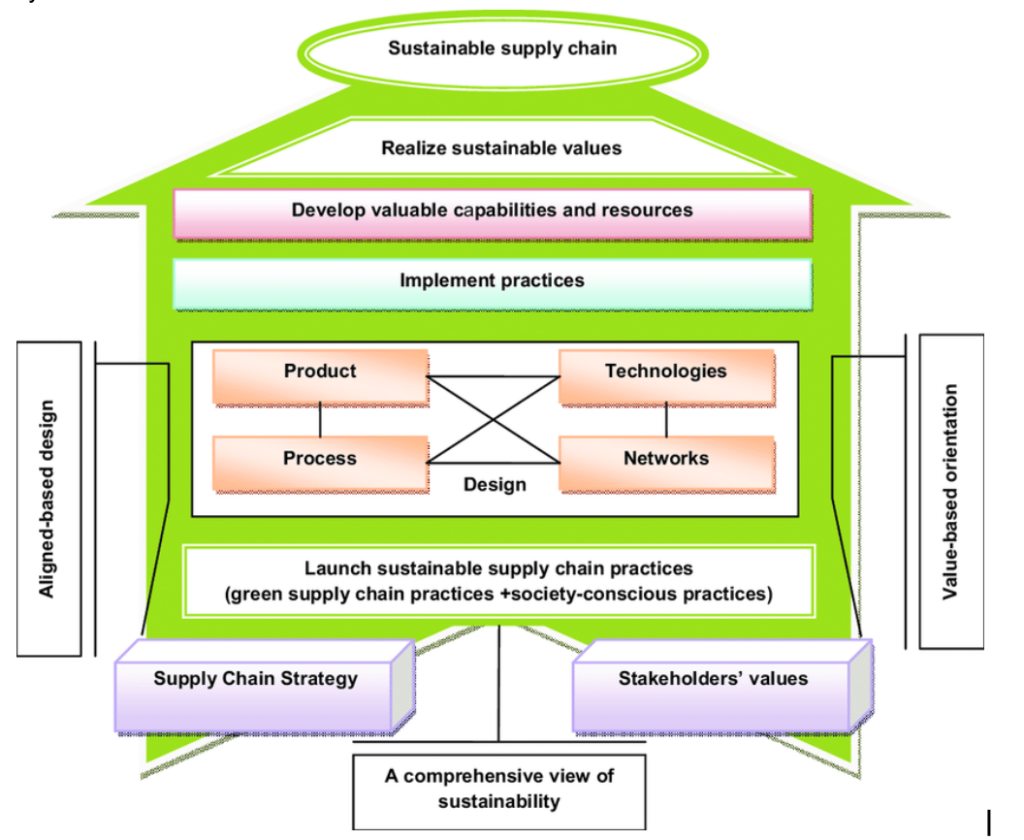

In response to the challenges posed by climate-based supply-chain disruptions, many companies have proposed and implemented plans to install Net-Zero Supply Chains. In doing so, they hope to mitigate the immediate threat posed by carbon emissions while creating a more sustainable framework.

However, many companies struggle in finding a way to implement such changes – after all, supply chains take years to develop, incorporate countless people and resources, and companies may balk at the cost of such an endeavor. However, each company (or even industry) can save on costs with careful planning, and by following the advice of experts.

For example, the World Economic Forum released seven core steps that companies of varying sizes can utilize to address their supply chain sustainability.

First, the WEF encourages company leadership to rethink its product’s design itself. For industries that do a significant amount of shipping, packaging, or even labeling, rethinking the product design in a more mindful way can be a great starting point in rebuilding one’s supply chain, as it instructs the company and their suppliers alike on what materials are necessary versus which could be altered or modified.

This leads to the second suggestion of embracing collaboration. Coming in with a strong concept of what changes are desired opens the door to communication between the many links in a supply chain, not only from company to supplier but among suppliers themselves. While this presents its own challenges such as working across timezones and country borders, it also presents the opportunity to reacquaint one’s business with the real-world players who bring the product into the marketplace, help inform all parties involved of their respective roles and capabilities, as well as keeping the door open to innovation throughout the restructuring process.

The last four suggestions relate to one of the most important (and consequently most challenging) aspects of restructuring any supply chain – financing. As their report notes, investing in climate technology and developing better data structures are key to building and maintaining a sustainable supply chain. It is fairly straightforward for any investor or investment entity to track returns and “successes” on individual climate tech projects. However, it can be challenging to justify a climate technology to stakeholders when the returns may take years to come to fruition. However, as climate technology advances it becomes more affordable, with the volume and diversification of products growing every year.

Global governments have expressed their willingness to support these ventures. For example, in 2021 during the Cop26 summit, world leaders representing two-thirds of the world’s economies stated they would “align standards and coordinate investments to speed up production and bring forward the ‘tipping point’ at which green technologies are more affordable and accessible than fossil-fueled alternatives”.

Finally, the WEF strongly recommends that companies think about policy and standards holistically rather than with a narrow lens. Holding to a “high but workable standard” can be challenging across a broad supply chain, whether it be national or international. However, in a post-pandemic business environment that continues to improve in efficiency and coordination, such a goal is not just aspirational but achievable. For example, just this year Starbucks debuted a new Partner Waste and Recycling App, which was designed to facilitate partners in navigating complex and unique store recycling guidelines to help reach the company’s goal of reducing waste by 50% in 2030.

What Does Net Zero Mean for Investors

While the environmental impacts of investing in sustainable supply chains are clear, it is also a prudent investment for stakeholders. In a study analyzed by the supply chain thinktank Supply Chain Brain, researchers found that across 250 global shipping companies, 67% reported that sustainable practices resulted in cost savings and 59% reported benefits to their company’s reputation. Further, the study found that fuel efficiency geared towards sustainability also reduced idle times, optimized routes to reduce fuel consumption, and led to the company more regularly utilizing alternative fuel sources – all ultimately saving money and improving return on investment. While investment to mitigate climate change typically sacrifices short-term returns for a business’s long-term viability, targeting such a critical source as a supply chain can result in a nexus between the two.

Conclusion

Supply chains are a puzzle for every business in the modern age, and it may seem like the only viable solution comes at the cost of the environment. However, as sustainability technology, infrastructure and general support grow, this need not be the case. By comprehensively evaluating one’s business for openings for sustainability, and opening conversations between themselves, suppliers, and financiers, companies can make great strides towards tackling the negative effects of climate change.

Leave a Reply